Handling to and from the warehouse: technology, infrastructure and integrated solutions for the automation and cost-abatement in manufacturing companies

OCME has developed internal logistics and handling solutions since 2003.

The growth of this sector, both in terms of turnover as well as applied technology, has accelerated considerably in recent years, thanks to the development of laser-guided vehicles and integrated logistics management and control technologies.

OCME has met this need by developing the necessary know-how thanks to a dedicated business unit, the logistics systems unit, which studies and produces innovative products and with unwavering development of both the system control software and the vehicles, adapting to the customers’ specific requirements.

OCME’s outstanding engineering abilities can also be seen in its ability to understand the customer’s actual equirements, foresee future development scenarios and organise a complex project that interacts with existing systems and infrastructure.

This is testified by our achievements to date, on behalf of the main leaders in the beverages, tissue and food industry in addition to major concerns in other industries, which have benefited from OCME logistics systems.

Logistics and end-of-line for Caviro

A complete end product handling system, spanning palletising to preparation of the shipping bays, all perfectly in synch with the automatic warehouse located onsite.

OCME and Robopac innovations for Mahou

Ocme and Robopac are working together to provide the best end-of-line solutions in the beverage sector to a key Spanish customer, Mahou.

ENOITALIA CHOOSES OCME'S LGV AURIGA VEHICLES

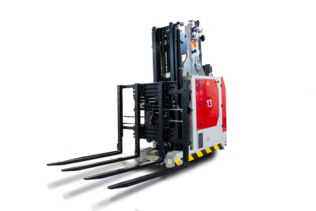

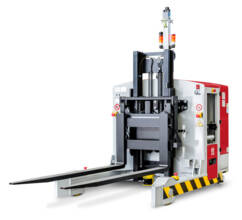

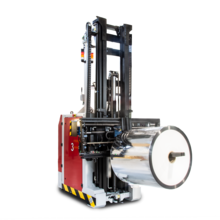

OCME supplied Enoitalia with 11 automatic Laser Guided Vehicles (LGV) of the Auriga series, which includes two models.

THE OCME LGVs SYSTEM JOINS VIOLETA

The company decided to rely on OCME's automatic solutions, to improve the performance of its warehouse and the working environment. The answer given by OCME in order to meet the needs of the industrial lay-out was providing two Auriga high-precision LGV lift trucks