Since the foundation date 1954,

thanks to the long-term experience of OCME to handle lube oil packaging solutions and the great relationships established with all the biggest worldwide lube oil producers, our engineering team ensures support and competence to design complete filling lines or to optimize an existing plant.

Lucas Oil a prestigious customer in the United States lube oil industry.

OCME lands a prestigious new customer in the United States lube oil industry. Based in Corona, California, Lucas Oil, has installed the Italian company’s filling and secondary packaging solutions for its range of lubricants and additives for automotive applications.

COLLABORATION WITH EXXONMOBIL Chemical AND RKW TO DEVELOP NEW PRINTED FILM CREATED WITH RECYCLED POLYMERS

In a new step towards sustainable packaging and technological evolution, OCME has worked together with suppliers ExxonMobil Chemical and RKW Group to develop a new type of high quality film made with virgin polyethylene from ExxonMobil and post-consumer recycled PE content.

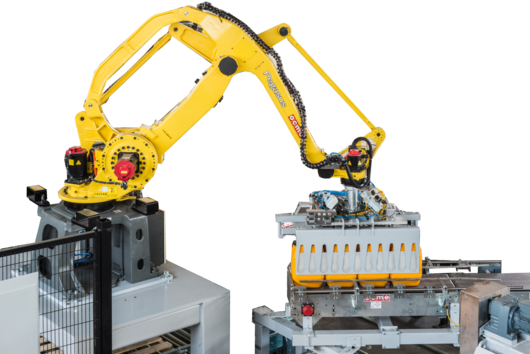

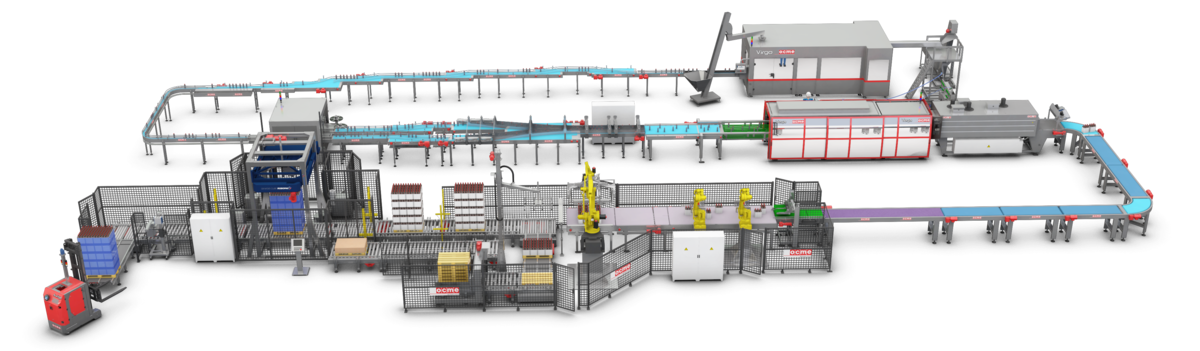

complete “turnkey” solution for Iconic Lubricants

The need to modernise plants and increase their functionality and productivity led Iconic Lubrificantes to look for a single, reliable partner that could guarantee the achievement of the objectives set. OCME was the right answer.