CLOROPAC Gravimetric filling and capping machine (chlorine based product)

The usage of materials resistant to the chlorine attack, combined with innovative manufacturing processes, provide the new CLOROPAC GRAVIMETRIC FILLING AND CAPPING MACHINE (CHLORINE BASED PRODUCT), greater durability, reliability and better performance. The equipment performs the filling and closing processes in a single block, using gravimetric concept valves. With application for chlorinated or corrosive products, in plastic bottles.

chiudi

Benefits di prodotto

reliability

Sistema construtivo que porporciona maior durabilidade (vida útil), confiabilidade e melhor desempenho.

Versatility

Versatility to fit in each client’s production according to their needs, through thto fit in each client’s production according to their needs, through the project adequacy and customization

HMI

It is developed with a friendly and intuitive interface, facilitating the programming of recipes and set up adjustments.

clean design

Build with SMED concept

TOOL KIT

Guarantees the conduction and stabilization of bottles, thus providing a better quality of filling.

INDUSTRY 4.0.

Possibility of integration of the entire line and low need for operator intervention.

SAFE

Machine designed in compliance with relevant safety and project standards.

overview

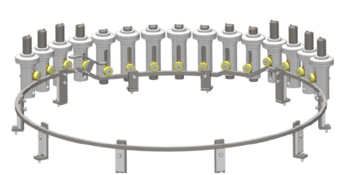

Designed to close bottles with different models of lids, acting with a closure system by magnetic heads with individual torque regulation for lids with common thread, fixed heads for pressure lids and special systems for lids of complex geometry.

Main structure (base) made of carbon steel and coated with rubberized paint and wrapped in engineering polymer, and all parts in contact with the product are made of engineering polymer and / or titanium.

Versatility to fit in each client’s production according to their needs, through the project adequacy and customization. Equipment developed and projected to fulfil the food, cosmetic, pharmaceutical, sanitizing and chemical industries, among others.

CLOROPAC GRAVIMETRIC FILLING AND CAPPING MACHINE

Option & schede prodotto

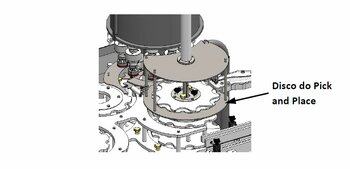

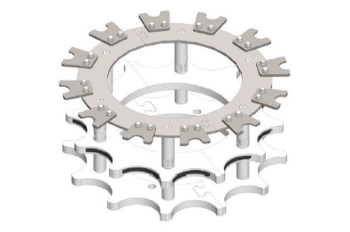

Pick and place disc made of AISI 904L stainless steel

Option made of material with superior performance in terms of oxidation resistance.

Piston plunger made of duplex stainless steel

The piston plungers are made of PVC as standard. As an option, we offer these made of duplex stainless steel (composition of two types of stainless steel) that provide high mechanical strength and corrosion resistance superior to 316 stainless steel. For applications that require greater effort from the plungers, the use of duplex stainless steel is the rule, to ensure greater durability and better performance even over time. For example: for applications in 5-liter flasks that have decentralized nozzle and for block base applications. The base plate of the bottle that is attached to the piston seat is made of AISI 904 stainless steel to provide greater resistance to corrosion.

Plate made of AISI 9041 stainless steel

External thread guide made in AISI 904L stainless steel

Option made of material with superior performance in terms of oxidation resistance.

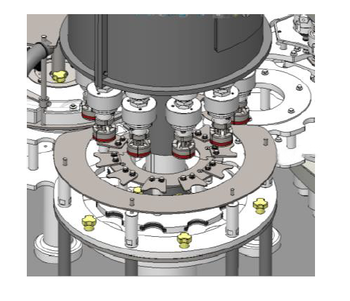

Grooved chestnuts made of duplex steel

Option made of material with superior performance in terms of oxidation resistance.

Threaded insert made of AISI 904L steel

Threaded insert is a part that supports the bottle by the neck while it receives the strain of the threading process. It is made of 316L stainless steel as standard. However, we do offer these parts in titanium as an option for increased durability and performance over time.

External self cleaning system

Torque limiting system

Devices installed in different points of the machine's transmission system that operate as a clutch whenever the machine is subjected to extra efforts or mechanical shocks resulting from some abnormal event in the process. For example, crushed bottles or any other object that accidentally enters the filling machine, causing collisions. Thus, the application of this device preserves the integrity of the equipment and contributes to a longer useful life.